What is sponge blasting?

It is crucial that the surface is prepared thoroughly in many cases. Blasting is not only required when removing rust from the substrate in order to reach the required purity but also for the required roughness for painting or coating.

The disadvantage of blasting with conventional methods (sand, grit, furnace slag) is dust and in several work areas such as paint shops, industrial installations and in the food industry the presence of jet dust is not permissible due to quality and hygiene regulations.

The sponge blasting method provides a solution for this. Thanks to the composition of the blast medium, the formation of dust is reduced by 98%.

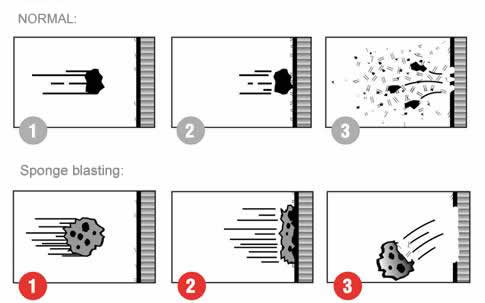

A polyurethane structure (the ‘sponge)‘ contains abrasive elements that may be adjusted to the nature of the substrate and the desired result. The biggest difference between conventional grit and the sponges becomes clear if we look at what happens when they impact the surface (see the figure below).

Blasting grit, for example, will pulverize on impact and will become dust just as the blasted surface does. When sponges are shot on to the surface they will open on impact, the abrasive pieces will do their job and the sponges will close again when they release the surface and will take the formed dust with them in their fall.